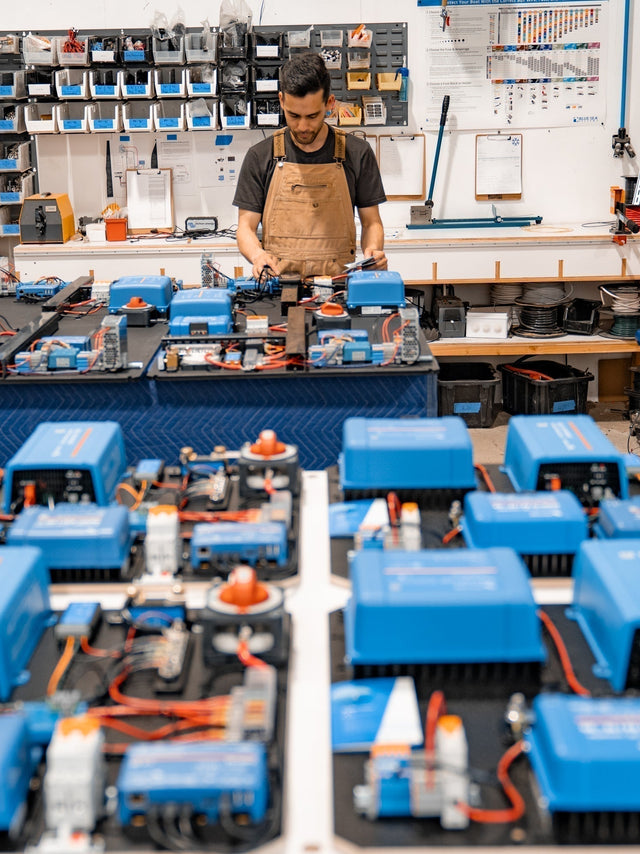

Powering Security Deployments

When it comes to field-deployed security systems, reliability and repeatability are everything. Artek supplies Danner's Logistics + Security, a leading provider of security monitoring solutions, with pre-wired, ready-to-install electrical panels that power their mobile deployments. For Danner's power solution, Artek designed a 24V 5Kw system using Victron Energy components that are supported by high-quality overcurrent protection and mounted to marine-grade Hexply.

Customizations & 3D Printing

Upon Danner's request, our team also developed custom mounting plates that indicate hookup locations for negative and positive cables on crucial terminals. This makes large-scale installations easier and safer for technicians. Implementing small details like these color-coded mounts also decrease the likelihood of on-site installation discrepancies, making these repeatable systems engineered for performance and consistency, but also field-service simplicity.

Integrated Capabilities, Streamlined Production

At Artek, our strength lies in doing more under one roof. Each panel delivered to Danner’s Security is the result of tight coordination between multiple departments working in unison:

-

Electrical Engineering: Our team designs each system to meet the unique demands of mobile surveillance and asset protection, ensuring optimal performance, safety, and compliance with best practices.

-

CNC Fabrication: Custom-cut backplates and mounting surfaces are precision-machined in-house for accurate, repeatable assembly.

-

3D Printing Services: We produce durable, labeled mounting plates that clearly identify hook-up locations for positive and negative terminals. This reduces installation time and minimizes errors in the field—enhancing both safety and clarity for technicians.

-

Manufacturing Optimization: From component placement to cable routing, we refine the build process for scalability, consistency, and ease of installation.

-

Installation Center: Artek supports Danner’s with hands-on integration and pre-deployment validation to ensure every system meets operational requirements.

Repeatable (& Expandable) Solutions at Scale

Because all aspects of design, fabrication, and assembly are handled in-house, Artek is able to offer Danner’s a repeatable and scalable solution that; Reduces field labor, shortens lead times, and maintains a high level of quality control across every deployment. Just as importantly, our fully integrated workflow allows us to respond quickly when system updates are needed. Whether it’s increasing battery capacity, expanding the solar array, or modifying component layouts, we can implement design changes rapidly without disrupting production—ensuring Danner’s systems continue to evolve with their operational requirements.